Various improvement methods are being used in the LED lighting industry. We’ll look at two case studies and then reference a video of how LED bulbs are made.

Case Study: Six Sigma and 5S Applied to LED Street Light Manufacture

In an article titled “Quality Improvement for LED Lights Using Six Sigma” Satyajeet Borawake discusses the application of Six Sigma and 5S to the manufacture of LED street lights.

He discusses the DMAIC phases and the results of applying 5S with LED lighting.

You can access his paper here.

Case Study: 5S and Ford 8D- Problem-solving Applied to LED Bulb Manufacture

In an article titled “Implementation of lean six sigma techniques in (or) at led-bulbs manufacturing company & any small scale industries to improve working standards” the authors Shakti Prasanna Khadanga and Surla Ganesh apply 5S and the Ford 8D Problem-solving methodology to the manufacture of LED bulbs.

They discuss the implementation of 5S before covering the application of the Ford 8D method.

Here are the Ford 8D Steps:

D0 – Planning Stage

D1- Establish the Team

D2- Describe the Problem

D3- Develop Interior Containment

D4 – Define Root Cause and ID Escape Point

NOTE: The escape point is the earliest control point in the control system following the root cause of a problem that should have detected that problem but failed to do so.

D5- Permanent Corrective Action (PCA)

D6- Implement PCA and Control Plan

D7 – Prevent Recurrence

D8 – Recognize team efforts

You can access their paper here.

To learn more about Ford 8D, here’s a video from IMA for the Manufacturers’ Forum.

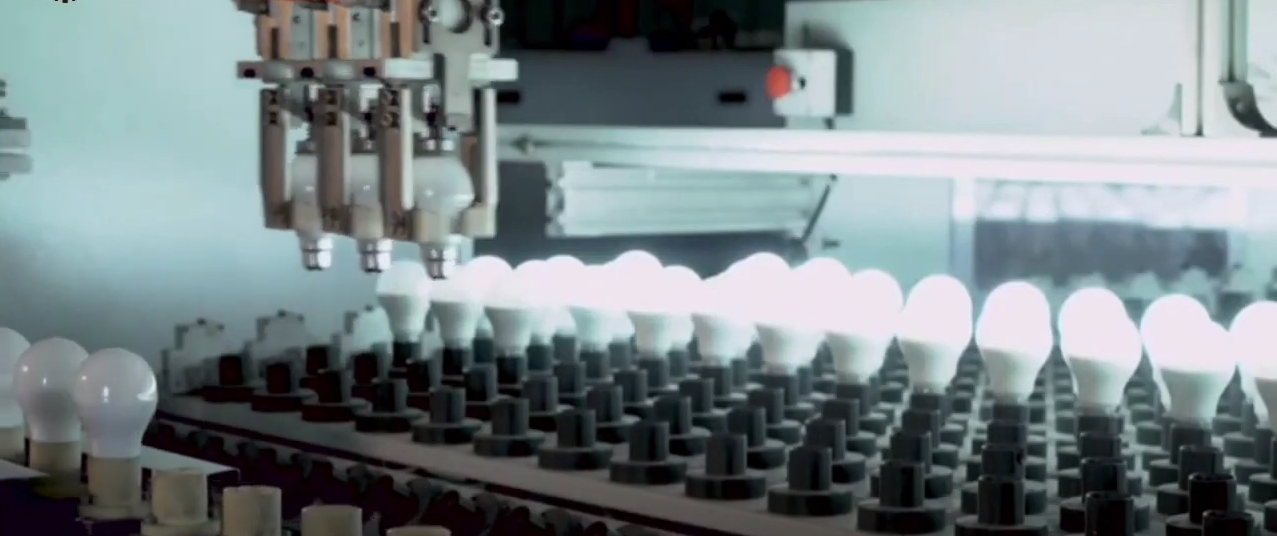

How LED Bulbs are Made

This is a video from Tech Machine on how LED bulbs are made by Havells of India

NOTE: The audio is in Hindi.

Leave A Comment