Treating and disposing of solid waste is an age-old problem. How can Lean Six Sigma help?

We’ll answer by exploring several cases:

- Reducing waste collection accidents

- Improving infectious waste disposal

- Reducing trash pickup costs

- Reducing solid waste transfer costs

- Improving aluminum can recycling rates

Reducing Waste Collection Accidents: Jakarta

Accidents can occur during solid waste collection. This study uses Six Sigma to reduce the incidence of accidents in South Jakarta.

The article titled “Six Sigma method approach in the prevention of occupational accidents on the solid waste collector in South Jakarta” was written by authors Dino Rimantho and Bambang Cahyadi.

During the Measure phase of DMAIC, the authors constructed a Pareto chart of the work accident categories.

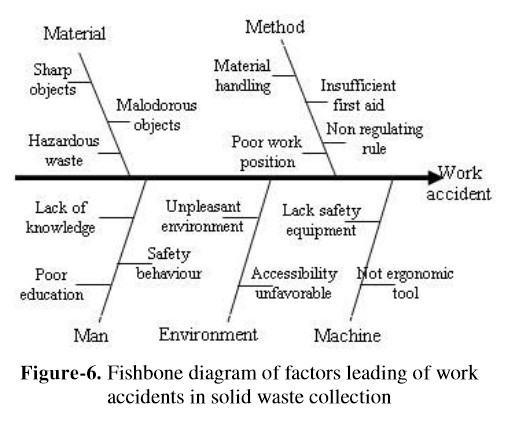

The following Fishbone diagram was developed during the Analyze phase.

In the Improve phase, the authors suggest solutions for the following:

- Lack of Safety Equipment

- Unpleasant Environment

- Sharp Objects

- Lack of Knowledge

- Non-regulating Rule for Safety

You can access the article here.

Improving Infectious Waste Disposal: Ohio

A great deal of waste is generated in hospitals. Much of it infectious.

In an article titled “Applying Lean Six Sigma methods to improve infectious waste management in hospitals” Nasim Nabiyouni and Matthew J. Franchetti discuss how Lean Six Sigma was applied.

Note: The study focused exclusively on the application of Lean tools.

The study addressed processes prior to the transfer of medical waste to a treatment center and processes followed after invoice and report receipt from the treatment center.

You can access the study here.

Reducing Trash Pickup Costs: Texas

Every municipality must have a provision for picking up trash.

This video chronicles a project using Lean Six Sigma to reduce trash pickup costs in the city of Tyler, Texas.

The project looked at customer call-in complaints over a 9 month period. Garbage misses accounted for 60% of the calls. Next, they did an analysis of what areas had the most misses. Once the North side of the city was identified as having the most call-ins, the project looked at the routes reflected in those call-ins.

This led to a project focus on one route and the costs associated with a garbage miss. Based on findings, recommendations were made to leverage improvement across other routes.

You can view the project presentation video here.

Reducing Solid Waste Transfer Costs: Florida

Miami-Dade County has three landfills and three regional waste transfer stations. Transfer operation expenses were higher than its expenses. This Green Belt Project attacked the problem using Six Sigma.

Based on data, the project focused on night shift vs day shift travel time. Night shifts accounted for more trips per average than day shifts.

The team developed countermeasures to attack the subsequent waste transfer costs.

You can access the thorough project presentation here.

Improving Aluminum Can Recycling Rates: Kentucky

Fayette County Kentucky had a large number of aluminum cans that were not being recycled per week. The County used Six Sigma to study the problem and recommend improvement.

Authors Subodh K. Das and Margaret Hughes document an initial study titled “Improving Aluminum Can Recycling Rates: A Six Sigma Study in Kentucky”

Based on data the large number of aluminum cans per week not recycled was identified as the main issue for the project.

The project documented application of the DMAIC phases and concluded with the next step recommendations:

- Determine the true recycling rate

- Continue to revise and finalize the process

- Document and implement projects of placing recycling bins in all elementary

- Ensure sustainability of improvements

- Recommend strategies for wider replication

You can read an overview of the study here.

Leave A Comment