In a high-speed time-lapse video, watch how nurses implement 5S in an ICU supply room to improve their workspace.

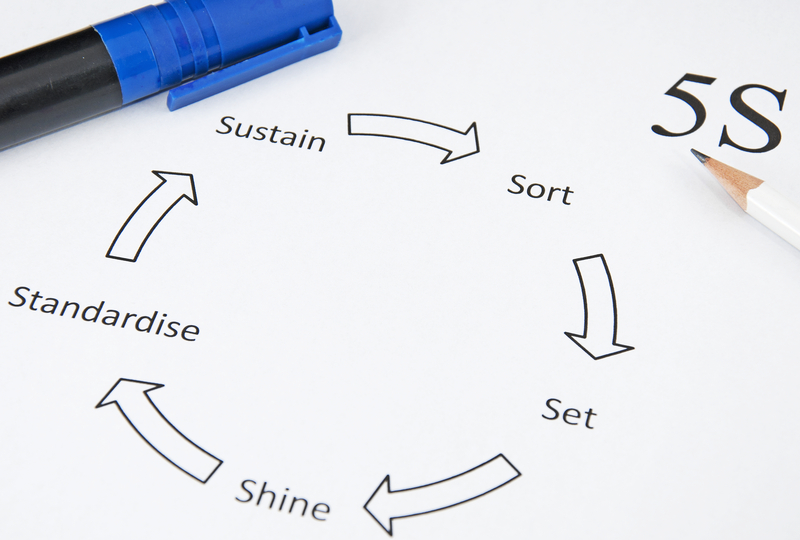

5S is a core tool used in the Lean methodology for business improvement. As indicated in the above picture, it consists of 5 steps:

- Sort

- Set in Order

- Shine

- Standardize

- Sustain

Let’s explore each of these as introduced in the video.

Sort:

- Get rid of unnecessary or expired items to make space for everything else

- Unnecessary

- Stored elsewhere

- Rarely used

- Patient specific

- Never used

- Replaced by different item

- If you’re not sure about something, put it aside for a few days to see if anyone needs it

- Categories Developed

- Expired stock

- Does not belong

- To be returned

- Overstock to be used

- Mystery items

- Obsolete items

Set in Order:

- A place for everything and everything in its place

- Use containers that hold exactly the right quantity to prevent overstock

- Try a two-bin system to manage inventory

- Time to restock +buffer = bin size

- Empty bin = time to reorder

- Label items (with pictures) so anyone can find them – or put them away

Shine:

- Spot problems quickly by keeping the area spotless

- Shine regularly

- If something is always in the wrong spot, maybe it needs a new home

Standardize:

- Make sure everyone is doing things the same way (the best way we know now)

Sustain:

- When clean is the new normal, it’s time to see what else you can improve

- Audit regularly

- Is everything in the right place?

- Is everything in the right quantity?

You can watch UHN’s fun and instructional video here.

You can find further examples of UHN’s use of Lean in the news stories listed here.

After seeing the video, are you considering documenting your own 5S efforts via video to encourage others to use 5S?

Leave A Comment