Lean and Six Sigma methodologies have been used in the oil and gas industry for many years. We’ll discuss three cases from United Arab Emirates, Oman, and Australia. Then we’ll see a short video on the moving of oil rigs.

Lean and Six Sigma Applications in the Oil and Gas Industry: United Arab Emirates

In a paper titled “Lean Six Sigma Applications in Oil and Gas Industry: Case Studies,” authors J.P. Atanas , C.C. Rodrigues, and R.J. Simmons outline the successful applications of Lean and Six Sigma by two major oil and gas industries in the United Arab Emirates.

Two successful case study projects are described in detail.

The first case study focused on rig-move optimization. After applying the Six Sigma methodology, a 61% improvement in rig-move performance was achieved.

The second case study addressed inventory optimization. As described in the conclusions, the rollout of inventory management provided increased inventory visibility with improved cycle counting up to 50% over two years.

You can access the article and the two case studies here.

Six Sigma Applied to Oil and Gas Drilling Budget Estimation: Oman

In a paper titled “Framework to Implement Six Sigma Methodology to Oil and Gas Drilling Budget Estimation,” authors Mahmood Al Kindi and Mujtaba Al Lawati provide a framework for incorporating Six Sigma methodology for the estimation of drilling budgets in order to minimize prediction errors.

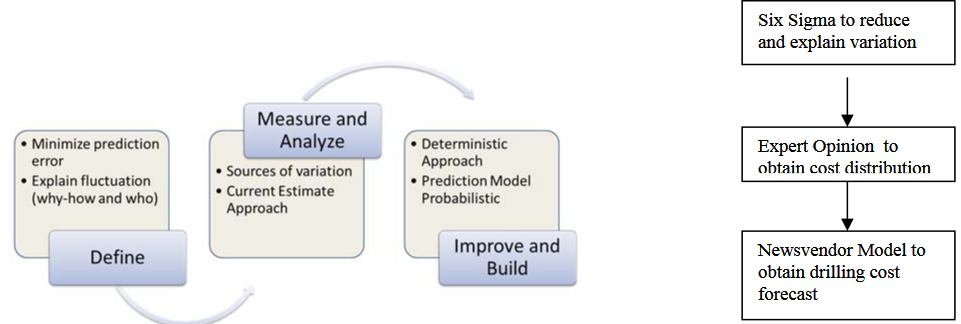

Their framework Figure 1 from the article is shown below.

The authors’ proposed model incorporated Six Sigma with Bayesian inference and a Newsvendor model to build a stochastic prediction model for oil and gas drilling cost estimation.

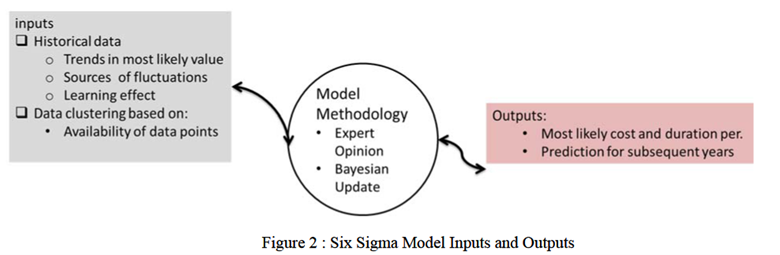

The Six Sigma model inputs and outputs as described in the article are shown below.

You can access the paper here.

Lean Implementation in Onshore Facilities to Reduce Waste: Australia

In a case study titled “Implementation of Lean Knowledge Work in Oil and Gas Industry – A Case Study from a Risk-Based Inspection Project,” authors Andika Rachman and R.M. Chandima Ratnayake discuss a case study of a Risk-Based Inspection (RBI) assessment project using Value Stream Mapping to identify waste and provide recommendations for future process improvements.

Project work was performed on onshore facilities located in Australia.

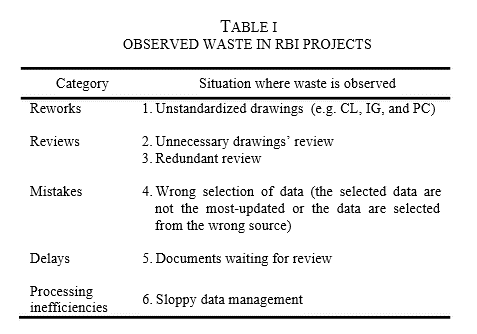

Identified wastes from the case study are shown below.

Three main recommendations for improvement were generated: standardization of

deliverables, elimination of unnecessary and redundant reviews, and systematic and standardized data management.

You can read the case study here.

Moving Oil Rigs with Link-Belt Cranes

See a short video from Link-Belt Cranes about oil rig moving.

You can watch the video here.

Leave A Comment