Bill Waddell, Lean manufacturing expert with over 30 years of experience and co-author of “Simple Excellence: Organizing and Aligning the Management Team in a Lean Transformation,” discusses the benefits of pairing Theory of Constraints (TOC) with Overall Equipment Effectiveness (OEE).

TOC focuses on determining the bottleneck on the overall performance of the process. It is generally widely understood.

OEE, on the other hand is less known. It focuses on a piece of equipment in a manufacturing process or a person in a non-manufacturing process and develops an overall metric that takes into account the availability for producing good items and the number actually produced.

As Bill mentions, it is an important companion to TOC. OEE should be used along with the machine or person that is the constraint for maximum benefit. Bill makes the point in his OEE introduction that “getting excellent OEE performance at bottleneck machines” has much more economic impact than just reducing defects.

Bill explains OEE using a simple manufacturing example, which we expand on here.

Focus on the flow through for the bottleneck piece of equipment in a manufacturing process.

Consider a bottleneck machine capable of only a throughput of 80 items an hour.

Suppose the constraint machine is available to run only 14 hours over a 16 hour two-shift period. Of those 14 hours, how many hours of good production time did we achieve?

Let’s say 13 hours, perhaps due to inexperienced operators.

Then of the 13 hours of production, what was the yield of the items produced? Perhaps this reduced production is the equivalent of another hour, perhaps due to rework.

So out of 16 hours over two shifts, we lost two hours when the machine wasn’t running, another hour perhaps due to inexperienced operators, and another hour due to reworking defective items.

While not mentioned in Bill’s basic introduction, the preferred calculation for OEE is the multiplication of three components: Availability, Performance, and Quality.

That is OEE = Availability X Performance X Quality.

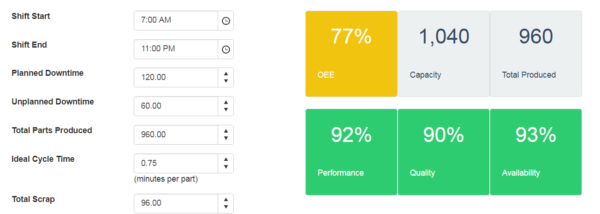

There are many free calculators for OEE online along with good explanations. We will focus on one from SensrTrx Corporation, a company that specializes in manufacturing analytics solutions.

Their calculator and explanations can be found here.

Let’s adapt Bill’s example as described previously for use in the OEE calculator. We will get a different number than he did as we’re using a more complete formula.

First, let’s focus on Availability.

Availability = Operating Time/Planned Production Time

In Bill’s example, the two-shift period is a total of 16 hours. But the machine is available only 14 hours. So, our planned production time is 14 hours x 60 minutes/hour or 840 minutes.

But we lost another hour of machine time to say, inexperienced operators for a total of 13 hours or 780 minutes of operating time.

Availability = 780/840 = 0.9286

Performance = Total Parts Produced/Ideal Capacity

In the performance calculation, we include all parts produced whether they are scrap or otherwise rejected. In Bill’s example, the constraint machine produced 80 parts an hour or one every 0.75 minutes. The Ideal Capacity therefore is 780 minutes x 1 part/0.75 minutes or 1040 parts.

But the operators in Bill’s example lost an hour because of reworking parts. In that hour they didn’t produce any new parts. So, the Total Parts Produced = 1040 – 80 = 960 parts.

Therefore Performance = 960/1040 = 0.0.9167

Finally, Quality = Total Good Parts Produced/Total Parts Produced

Here we need to make an assumption which wasn’t mentioned directly in Bill’s example; that is how many parts were actually defective and weren’t part of those reworked and accepted. Let’s assume that the machine has a 10% defect rate. Therefore, we scrapped 96 parts leaving 864 good parts.

Quality = 864/960 = 0.9000

In conclusion,

OEE = Availability X Performance X Quality = 0.9286 x 0.9167 x 0.9000 = 0.766 or 77%

We show the final result using the SensrTrx calculator.

NOTE: The OEE = AxPXQ formula allows us to look at all the pieces producing effectiveness which is preferred.

However, if one just wanted the OEE number, then there is a simpler formula which can be derived by substituting all the equation components into the AXPXQ formula and reducing it to the simplest terms.

OEE = (Good Products Produced x Ideal Cycle Time)/Planned Production Time

Let’s calculate OEE using this simpler form.

OEE = (864 good parts produced x 0.75 mins/part)/840 minutes = 0.77 =77%.

Again, however, the preferred formula is the one with all the components: Availability, Performance, and Quality.

You can view Bill’s introductory video here.

Leave A Comment